|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

Published on September 18,2021

Published on September 18,2021

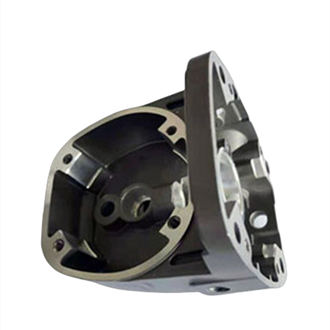

The density of aluminum alloy die castings is lower than that of cast iron and cast steel, but the specific strength is higher. Therefore, the weight of mechanical structure can be reduced by using aluminum alloy castings under the same load condition. This feature of aluminum alloy die casting just meets the requirements of high strength and low weight of parts for power tools, so in the power tool industry, aluminum alloy die casting has been widely used.

Published on September 21,2021

Published on September 21,2021

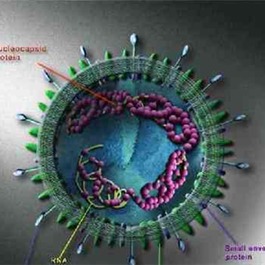

Energy security and environmental issues are always attached great importance to all countries in the world. Automobile energy conservation and emission reduction is of great significance to improve energy security and environmental issues, and has gradually become a key monitoring content of various countries.

To realize energy saving and consumption reduction, lightweight is the easiest and most effective first choice for many automobile enterprises. In the lightweight path, lightweight materials are the most widely used. Comparative analysis of the United States, Europe, Japan, China's automotive lightweight development route, material lightweight is the choice of the masses. Among automotive lightweight materials, aluminum alloy materials have higher comprehensive cost performance than steel, magnesium, plastic and composite materials, which have comparative advantages in application technology, operation safety and recycling. Therefore, aluminum alloy is the preferred material for automotive lightweight at present.

According to the prediction of international Aluminum Association, in the next few years, the single automobile aluminum used in the automobile industry will reach 234.35kg, and the corresponding aluminum die-casting will account for 61%. The market capacity of Aluminum die-casting in China will reach 244.897 billion yuan, with a compound annual growth rate of 7%. Such a huge market is an opportunity that many aluminum die casting enterprises cannot give up. As we all know, China is the largest aluminum producer in the world, with aluminum output reaching 37.08 million tons in 2020. Together with labor and other favorable factors, China's aluminum alloy die casting enterprises are globally competitive. Of course, to win the future market, China's aluminum alloy die casting enterprises still need to work hard on products, technology and customer layout, so as to reduce costs, improve profits and expand market share.

Published on September 30,2021

Published on September 30,2021

Power tools have been widely used in all walks of life for a long time, eliminating heavy manual labor for workers and improving production efficiency. In the tool market, power tools are witnessing exciting trends and innovations. Here are some of the trends driving today's power tools market:

1.Cordless power tools

Power tools have been transformed from wired power tools to cordless power tools.While sales of wired tools are still substantial, the shift to cordless tools has been dramatic. Cordless power tools include many battery-powered tools such as band saws, circular saws, crimping machines, hammer drills, impact drivers, impact wrenches, etc. These tools are ideal for welding, grinding, cutting, metalworking and other applications. The shift to cordless power tools shows a desire for tool convenience.

2.Application of lithium ion battery in power tools

With the increasing popularity of cordless power tools, the length of battery life has become one of the important properties of these devices. As a result, another shift in the power tool market is underway, with lithium-ion batteries gradually replacing nickel-cadmium or nickel-metal-hydride batteries. Lithium-ion batteries are smaller, lighter and do not self-discharge, so they can last for months while maintaining their useful life. Lithium-ion batteries also offer higher energy density or longer running time in a smaller package size, making them more efficient. This allows the battery to absorb more current and operate for longer periods than a nickel-cadmium battery. Lithium-ion batteries can maintain an average of 12 months of usable power, while nickel-cadmium batteries run out after only a few months.Today's cordless tools also run longer on a single charge than in past years.

3.Continuous development of new products

In addition to growing sales of existing power tools and lithium-ion batteries, the proportion of new products is also on the rise. Major power tool companies have been implementing research and development efforts to increase the market share of their brands. In terms of new product development, there are two directions of research and development worth noting. One is the versatility of the battery, which can automatically change its voltage depending on the tool in use. Another is faster charging time.

In the next few years, the market for power tools will continue to rise. As demand on an international scale rises, more manufacturers will enter the market and compete with the major players, which may help power tools continue to innovate.

Published on October 9,2021

Published on October 9,2021

As we move into the second half of 2021, countries around the world, including the United States, Spain, France and Germany, are beginning to see promising declines in COVID-19 infection and death rates. Thanks to an increase in vaccination, more economies are able to open up again, and many hope to return to normal as soon as possible.

But we know that globally, the epidemic is far from over. Until there is a fair increase in vaccination rates worldwide, we will continue to see significant impacts of the pandemic on the global economy and business, particularly supply chains.

The COVID-19 pandemic has had an unprecedented impact on global supply chains. Reduced capacity, poor functionality and supply chain disruptions are occurring at every link in supply chains across industries around the world.

In fact, a staggering 75 percent of companies reported losing $4 trillion in 2020 revenue due to supply chain disruptions during the pandemic and causing significant damage to their brands.

"Supply chain and procurement are key drivers of sustainable competitive advantage, but despite spending millions of dollars on ERP solutions, most global companies are unable to effectively manage complex global supply chains in the face of uncertainty," said John Piatek, VICE President, GEP. Moving into a post-pandemic world, companies must take a multi-pronged approach to managing supply chain risk if they are to remain competitive.

The pandemic has revealed key holes and blind spots in global supply chains. This has led to a shift in strategic priorities as business leaders work to stabilise their supply chains and mitigate future risks.

Not surprisingly, at the top of the priority list is supply chain visibility. The lack of visibility into their complete supply chain pattern means that many companies were caught flat-footed when the pandemic hit - and they are not interested in making that mistake again. Visibility will play a key role in identifying risks and addressing vulnerabilities before they cause significant damage over the next 12-36 months.

But visibility is not the only solution. Other new priorities include:

In a survey by Ernst & Young in late 2020, 61 percent of respondents said they would retrain their workforce in the next year to help employees use digital technology, operate equipment with health and safety in mind, and adapt to changing company strategies.

The same survey found a growing focus on investments in automation, artificial intelligence and machine learning, with 37 percent of respondents already using these technologies and another 36 percent planning to adopt them soon.

The company learned the hard way how risky it is to rely on a few suppliers. While linear supply chains improve efficiency, they face higher risks. Now, many companies are diversifying their supply networks to increase resilience and stability and thus efficiency. This includes not only adding backup suppliers, but also finding suppliers that may be more costly but operate in less risky markets and can deliver goods quickly.

To better understand their supply chain and improve visibility from end to end, companies need to prioritize and invest in better supplier intelligence. The right supplier intelligence solutions not only provide more proven and reliable data, but also provide proactive monitoring and deeper supplier research and benchmarking to help companies pre-emptively mitigate risks.

Digitisation is key to increasing supply chain visibility and accurately sourcing, evaluating and monitoring suppliers. As companies invest in digital supply chain management solutions, they will have the ability to better understand the supplier landscape, fully diversify their supply chain, identify potential risks, and proactively respond to threats before they become major disruptions.

|

Our goal is to provide every customer with a wide range of capabilities, competitive prices, superior quality and service. |

|

|||||||

|

Saving Your Time and Money |

|||||||||