|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

The process uses high pressure to inject liquid alloy metal into a reusable steel mold and then rapid cooling to solidify the alloy metal into its final shape. The problem of casting thin wall and complex structure is solved and the production cycle is shortened.

We are very familiar with the strict requirements for components in consumer goods, security monitoring and rehabilitation care industries, in which we have more than 20 years of experience. This is also an important factor for customers to choose to work with us.

Die casting process through the molten alloy filling mold under high pressure and high speed, and under high pressure crystallization solidification forming castings. We have 5 die casting machines ranging from 30 tons to 350 tons. All die casting machines are equipped with manipulator, which eliminates the potential safety hazards in production. For customers with subsequent machining requirements, we are equipped with CNC machining centers and CNC lathes, which can perform precision machining of castings according to customer requirements. We can manufacture alloy die castings from several hundred grams to several kilograms, especially for some thin wall and complex structure parts.

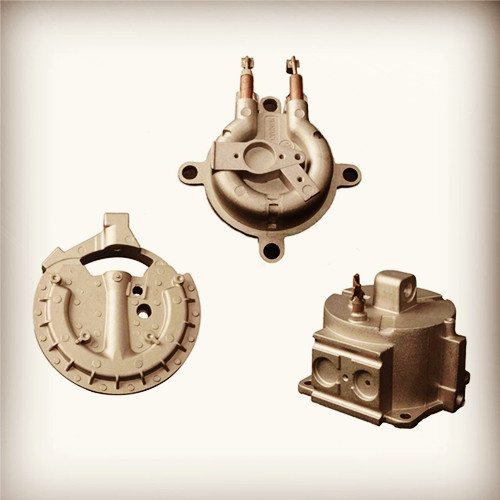

Die-casting parts, especially aluminum die-casting parts, are widely used in transportation, consumer goods, security, communications, electromechanical, aerospace, precision instruments, garden machinery, household appliances, daily hardware, power construction, rehabilitation and nursing, architectural decoration and many other industries. Such as all kinds of base, bracket, end cover, shell, flange, radiator, guardrail, handle, hinge, hub, and other special-shaped parts.

Fost manufactures components for a wide range of industries -- from ordinary consumer goods to highly regulated industries.

Expert manufacturing methodology and own core production plant – quickly scale from prototype to mass production without losing quality. We keep an eye on the factory floor and ensure secure supply while you focus on your core business.

The aluminum alloy material used in die casting has good fluidity and plasticity, so it can make a variety of complex shapes, difficult die casting, this process is especially conducive to casting thin wall and complex structure of castings.

The parts produced by alloy die casting process have higher precision and surface finish, which saves a lot of subsequent machining sequence and greatly reduces the labor intensity of workers.

Production of parts with the same function, the traditional process is long, waste more materials, and the use of die casting process to save electricity, metal materials, save processing time, so the cost is lower, the production cycle is faster.

Some application scenarios require not only high physical properties but also light mass of parts, such as automotive structural parts and power tool shells. In die casting, aluminum alloy can meet these requirements and produce parts with light weight and good physical properties.

There are 5 die-casting machines of 400 tons, 280 tons and 160 tons in total. Using automatic manipulator operating system, using environmental protection and clean energy natural gas for melting heat preservation.

● Zinc alloy

● Aluminum alloy

● We take customer trust seriously, employing proven quality management principles to enhance customer satisfaction and continually improve our performance and capabilities.

● We are very familiar with the strict requirements for components in consumer goods, security monitoring and rehabilitation care industries, in which we have more than 20 years of experience. This is also an important factor for customers to choose to work with us.

Parts and products produced by die casting are used in many industries, including but not limited to the following:

|

|

|

Consumer Goods

|

Security Monitoring

|

Rehabilitation Nursing

|

We manufacture and supply customized products and provide surface treatment services according to customers' specifications and industry standards. We are an efficient and cost-effective one-stop solution provider with the scale and capability to deliver integrated services.

|

|

|

Die Casting

|

Stamping

|

Surface Finishing

|

|

Our goal is to provide every customer with a wide range of capabilities, competitive prices, superior quality and service. |

|

|||||||

|

Saving Your Time and Money |

|||||||||