|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

|

Hardware accessories & Care equipment | Mobile phone:+86 13961213735 Whatsapp:+86 13961213735 E-mail:davey@fost.biz |

The process uses digital technology to control the machine's machining operations, removing the necessary materials from the workpiece to produce custom-designed parts.It solves the problems of various parts, small batch, complex shape and high precision, and realizes the high efficiency and automation of machining.

We are very familiar with the strict requirements for components in consumer goods, security monitoring and rehabilitation care industries, in which we have more than 20 years of experience. This is also an important factor for customers to choose to work with us.

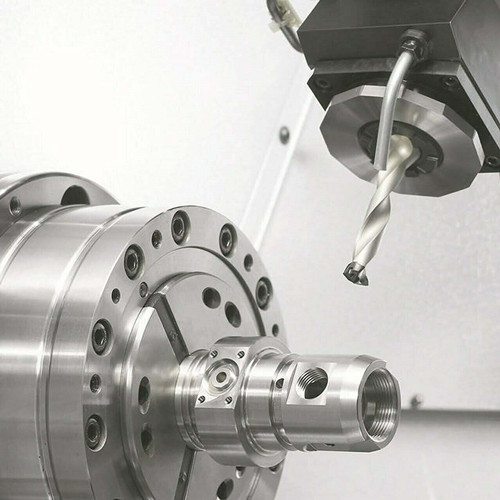

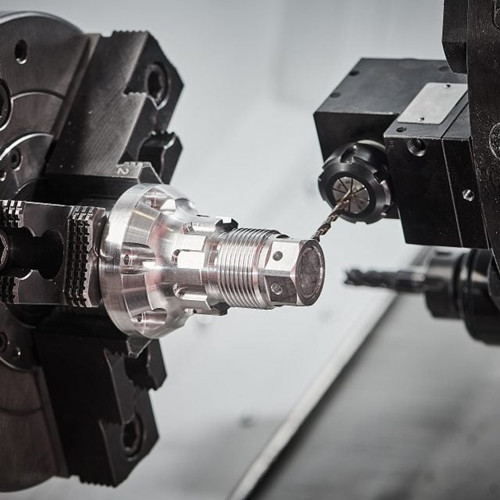

The CNC machining process involves the removal of material from a spinning workpiece. Our CNC turning machines consists of both single and multi-spindle lathes. All CNC machines equipped live tooling for cross-drilling and tapping and various milling configurations. We can complete parts will threads, thru holes, and even cross-holes, side mill and tuning operations precisely and at high speeds. Our twin spindle machine can perform both front and back work, which in many cases eliminates the need for multiple operations.

Parts produced by this type of machining are commonly found in automotive, aerospace, medical, marine and hydraulic industries. Such as headers, housings, shafts, shells, knobs, rotors, terminals, fittings, pistons, valve stems and similar products.

Fost manufactures components for a wide range of industries -- from ordinary consumer goods to highly regulated industries.

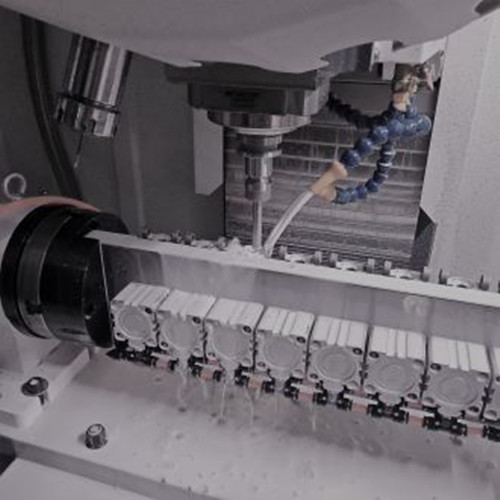

From small batches of a few hundred pieces to large batches of hundreds of thousands, CNC machining allows us to manufacture complex components on one machine. This allows us to meet designer's unique specifications of even the most demanding applications.

CNC machines allow for the replication of the same component thousands of times over, with each piece produced having the same dimensions as the previous. Additionally, the computerized controls enable industry professionals to achieve a higher level of precision than is generally possible with manual machining methods.

The CNC machining process also carries the potential for substantial time savings. With traditional machining equipment, operators must manually configure and set up the machine for each operation. In contrast, CNC machining equipment can make the necessary changes by a simple adjustment in the computer code. Additionally, while humans need breaks, these machines can operate consistently for more extended periods, allowing them to fulfill orders in a shorter time period.

CNC machining is suitable for both prototyping and production runs. As the process does not require intensive machine and tool preparation—instead using a CAD file—it's possible to quickly and accurately produce a prototype. Once a part design is approved, it can then proceed to full-scale production.

CNC machining operations accommodate a wide range of designs in metal, polymer, and other materials. This versatility makes them suitable for the manufacture of numerous different parts and products.

Our facility is set-up to meet your needs on everything from rapid proto-types to high volume production runs, and is equipped with the latest 3 & 4 axis CNC milling and turning centers, CNC drilling and tapping center and various equipment for secondary finishing operations,which provides the possibility for more complex and precise applications.

● Metals (e.g., stainless steel, carbon steel, aluminum, brass)

● Exotics Alloys (e.g., Hastelloy and Inconel)

● Plastics (e.g., PEEK, Delrin and Acetal)

● We take customer trust seriously, employing proven quality management principles to enhance customer satisfaction and continually improve our performance and capabilities.

● We are very familiar with the strict requirements for components in consumer goods, security monitoring and rehabilitation care industries, in which we have more than 20 years of experience. This is also an important factor for customers to choose to work with us.

Parts and products produced by CNC machining are used in many industries, including but not limited to the following:

|

|

|

Consumer Goods

|

Security Monitoring

|

Rehabilitation Nursing

|

We manufacture and supply customized products and provide surface treatment services according to customers' specifications and industry standards. We are an efficient and cost-effective one-stop solution provider with the scale and capability to deliver integrated services.

|

|

|

Die Casting

|

Stamping

|

Surface Finishing

|

|

Our goal is to provide every customer with a wide range of capabilities, competitive prices, superior quality and service. |

|

|||||||

|

Saving Your Time and Money |

|||||||||